Fast Parts: CAD / CAM / CAE Design

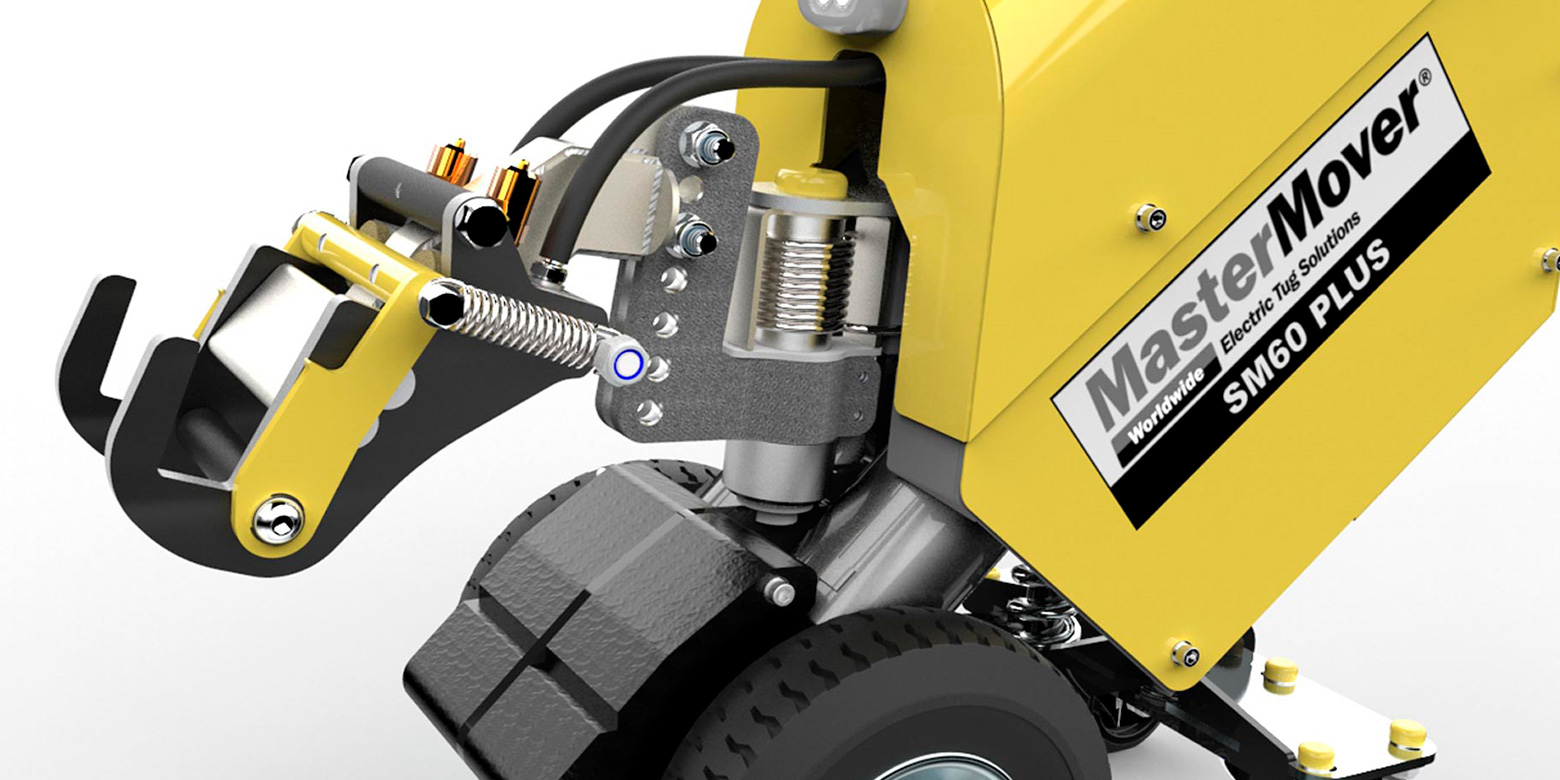

All the works carried out by the Fast Parts design team are characterized by the use of the Solid Edge and Fusion 360 design systems, two highly sophisticated software, ideal for integrating the different phases of the Design and Communication between CAD/CAM processes, also focusing on the "Design for 3D Printing".

These two systems provide a portfolio of design solutions without limits.

Solid Edge's synchronous technology and Fusion 360's cloud platform offer comprehensive capabilities for collaborative development of the product also through the use of mobile devices, with the possibility of designing anywhere and at any time. This is made possible because graphic computing and rendering are also cloud-assisted.

GENERATIVE DESIGN, FUSION 360

Generative design is a feature of Fusion 360. It is a very powerful tool capable of optimizing the geometry and design of the product according to the imposed constraints. In fact, it is possible to reduce the weight of the part while maintaining the standards relating to performance and respecting the engineering constraints.

Find out more about Generative Design and our services

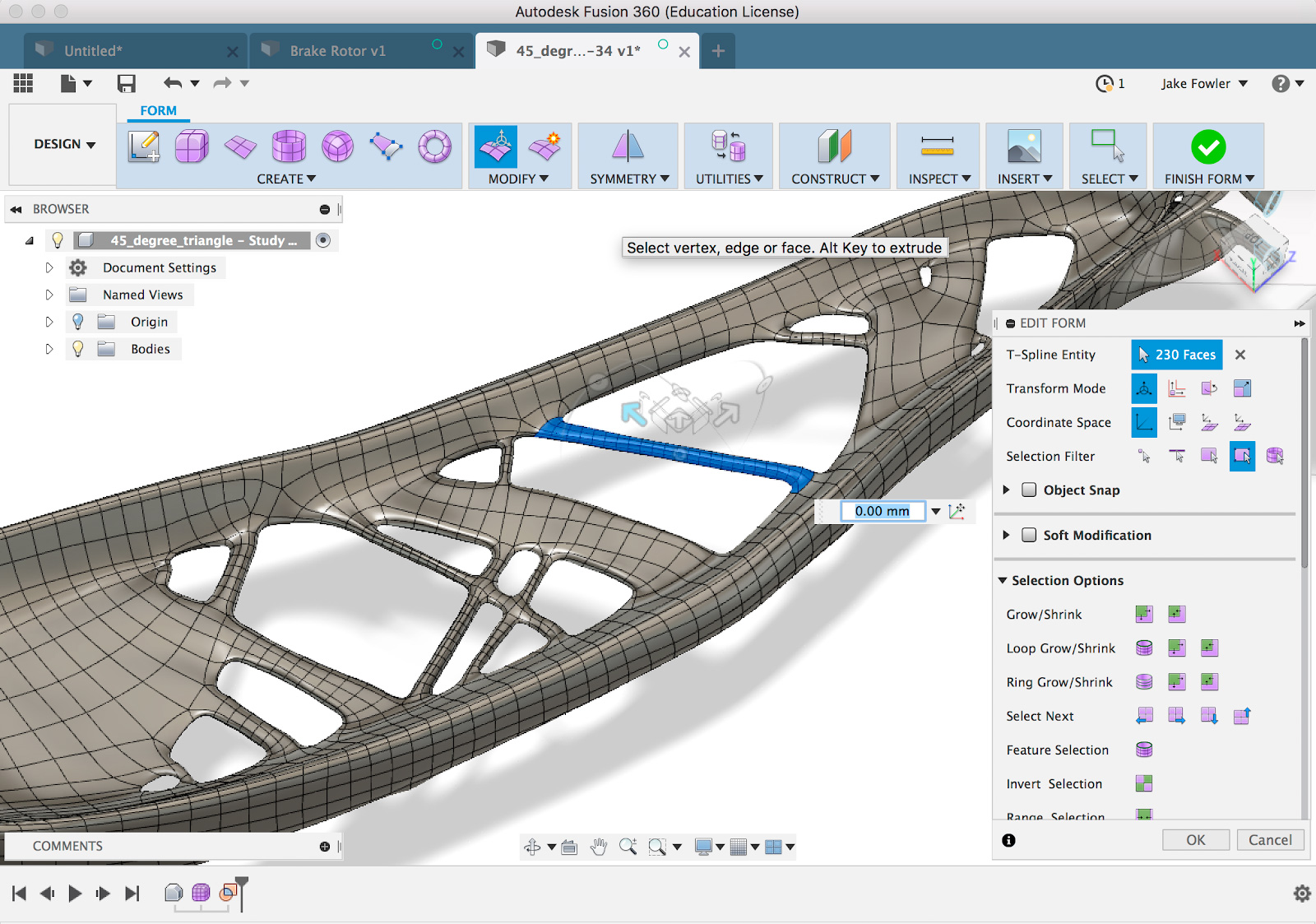

T-SPLINE, FUSION 360

Fusion 360 has recently integrated the Sculpt/Form workspace among its workspaces, which allows you to model three-dimensional objects using T-Splines (born as a Rhinoceros plug-in). T-Splines allow you to sculpt freehand shapes from a conceptual sketch by creating T-Spline primitives for three-dimensional structure.

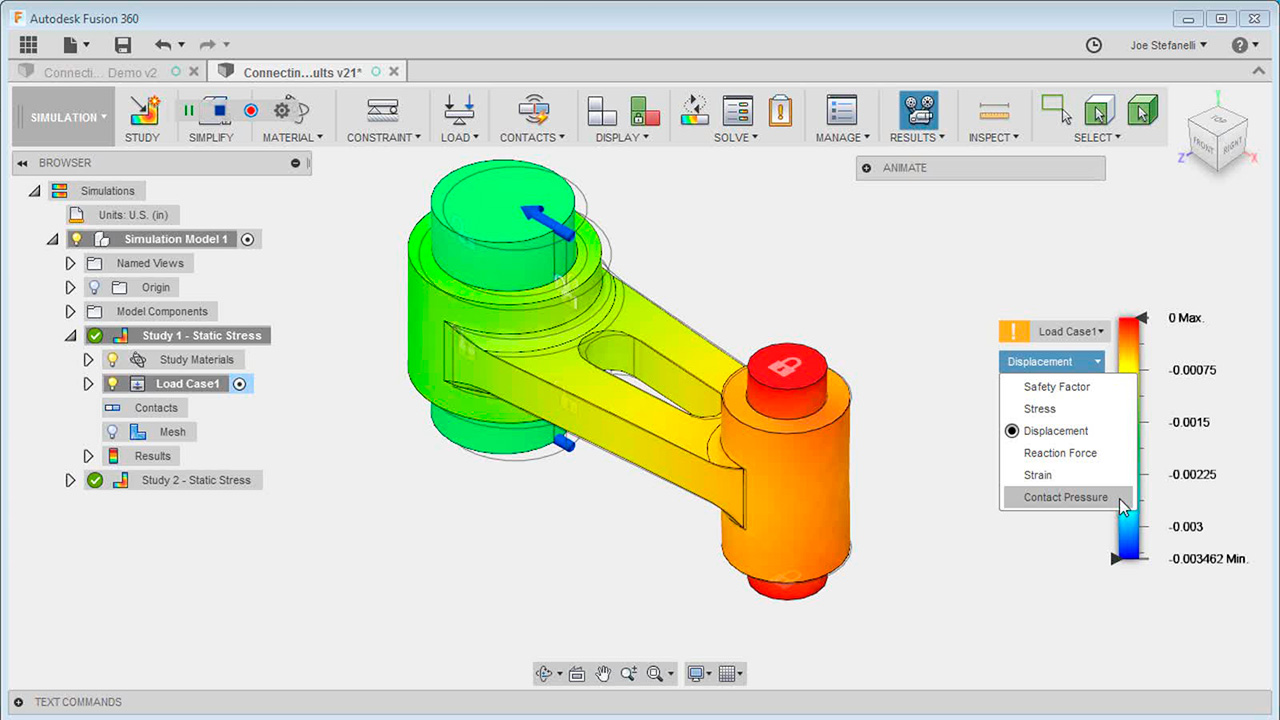

SIMULATION, FUSION 360

The Simulation workspace challenges designed products and components, digitally, while reducing prototyping costs.

LThe various types of simulators implemented in the software allow the following analyses to be performed:

- Cloud Simulation

- Study Breadth

- Simplify

- Compare Results

- Static Stress

- Modal Frequency

- Thermal & Thermal Stress

- Buckling

- Non-linear Stress

- Event Simulation

- Shape Optimization

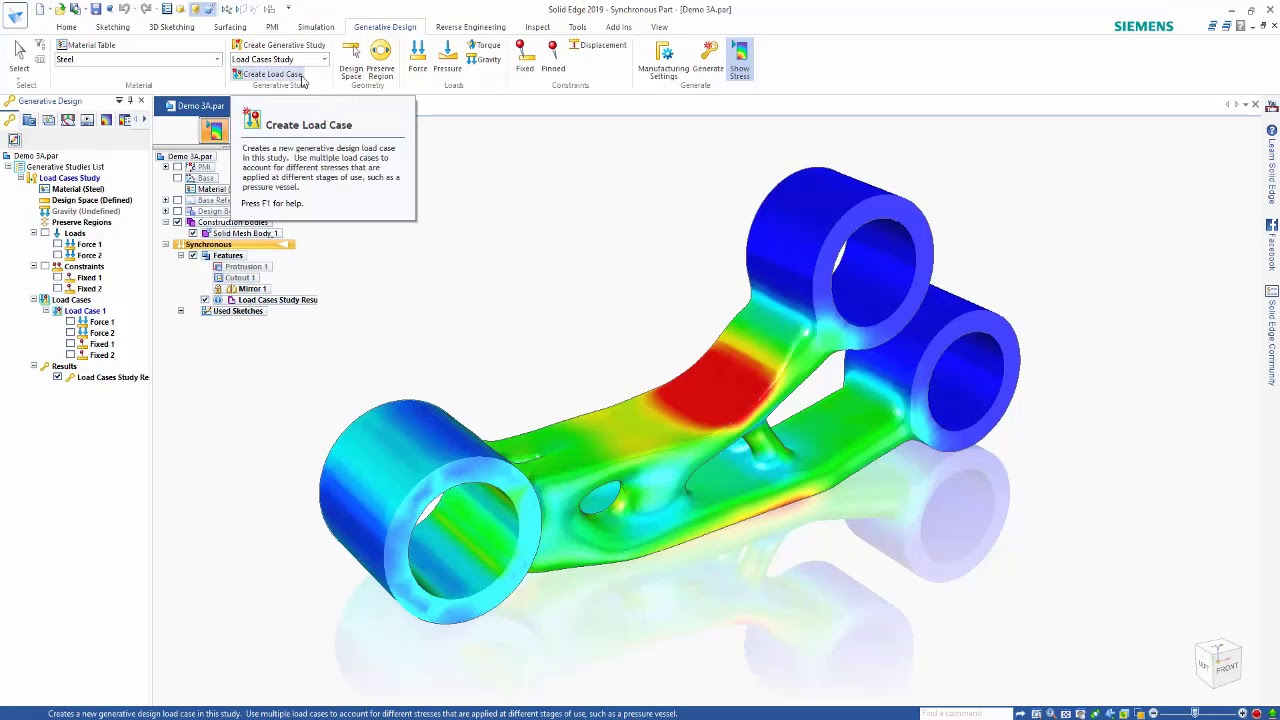

SYNCHRONOUS TECHNOLOGY, SOLID EDGE

Solid Edge's synchronous technology lets you quickly create new conceptual designs, easily respond to change requests, and make simultaneous updates to multiple parts within an assembly. This level of flexibility in the design eliminates complex pre-planning phases and avoids errors in features, rework and lengthy rework. The power of synchronous technology also allows you to manage data from different CAD systems as if they were native files, facilitating collaboration with suppliers and partners.

SIMULATION, SOLID EDGE

Solid Edge simulation capabilities range from single part simulation to assembly analysis, from definition and analysis of complete systems to computational fluid dynamics (CFD).

- Finite Element Analysis (FEA) allows designers to digitally validate component and assembly designs within the Solid Edge environment. Based on Femap technology and the NX Nastran solver, Solid Edge Simulation significantly reduces the need for physical prototyping, while reducing prototyping costs and time to market.

- FloEFD for Solid Edge is the only analysis tool for computational fluid dynamics (CFD). If CFD simulation is anticipated early in the design process, engineers can examine trends and discount less suitable options.

Contact us for more information