Raise3D Hyper Farm: cloud management of a fleet of printers and different technologies

3D printing today has a fundamental role as a production process, finding its place in the on-demand and in-house creation of medium/small sized components and for small batches, for which it is not convenient to use molds.

To adequately respond to market demand, the need to set up a print farm within your production cycle becomes crucial. A print farm refers to a set of 3D printers connected and managed through a centralized system, with the aim of increasing productivity and reducing machine downtime. The fundamental requirements for an efficient print farm are the speed and repeatability of the process, reliability, large print volume, wide range of usable materials and simple, remote management.

At FastParts we have identified all these features in the Raise3D system, consisting of the IdeaMaker slicing software, a fleet of professional 3D printers using FFF filament and DLP resin technology and the remote management platform, the RaiseCloud.

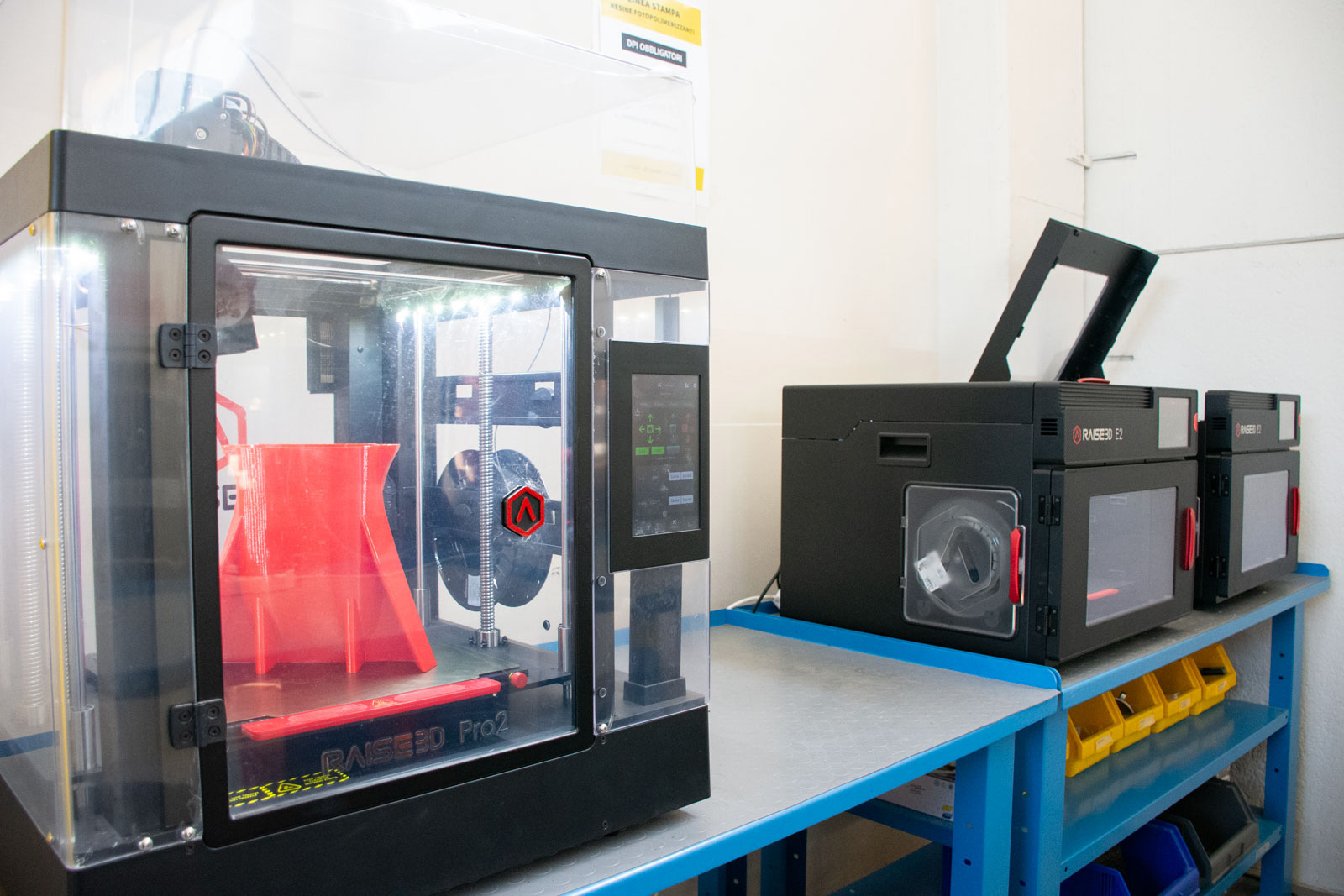

Currently in our production line there is a print farm of seven Raise3D printers which includes: two printers from the Pro series (Pro3/Pro2), three from the E2/E2CF series, the Forge1 printer for printing metal filaments and the new resin DLP system (DF2 3D printer + DF Wash + DF Cure).

Why use a print farm with Raise3D printers?

Raise3D offers a wide range of solutions to satisfy the most varied production needs. The main advantages are:

- Access to different 3D printing technologies: Raise3D over the years has dedicated itself to the creation of industrial machinery for the 3D printing of polymers using filament technology (FFF). However, it has recently expanded its portfolio to include MetalFFF technology for the 3D printing of metal filaments (the Forge1 3D printer allows you to print 316L and 17-4 PH stainless steel) and DLP technology for photosensitive resin (DF2 system).

Having different printing technologies in the same system allows you to choose the best solution for each customer request, from prototyping to the creation of final parts; - High speed and print volume: Pro series printers have large print sizes of up to 300x300x600 mm; they also allow you to print in hyper speed mode, reaching speeds of up to 350 mm/s without compromising surface quality. In this way it is possible to create medium-large format components up to three times faster, while ensuring high precision.

- High productivity: thanks to the IDEX (Independent Dual Extrusion) printing system present on the E2/E2CF series printers, the two extruders can operate independently of each other, offering the possibility of duplicating or mirroring a model at the same time. In this way, productivity is doubled in the same printing time, ideal for small and medium quantity runs;

- Open material system to choose from a wide range of polymers and resins, including those with high mechanical and thermal characteristics such as PPS-CF or RG3280 ceramic and RG9400 flame retardant resins;

- Simple software management: thanks to the IdeaMaker slicing software we have all Raise3D technologies and solutions on a single interface, facilitating operations during the print preparation phase and allowing projects to be sent to the machines remotely.

RaiseCloud

Knowing how to control and manage the print farm is fundamental. RaiseCloud is Raise3D's cloud platform for managing machines remotely. In this way it is possible:

- Have centralized management of print projects

- Check with a team the progress of the production line and print queue

- Extrapolate production data to predict the trend of requests and detect any inefficiencies in the workflow