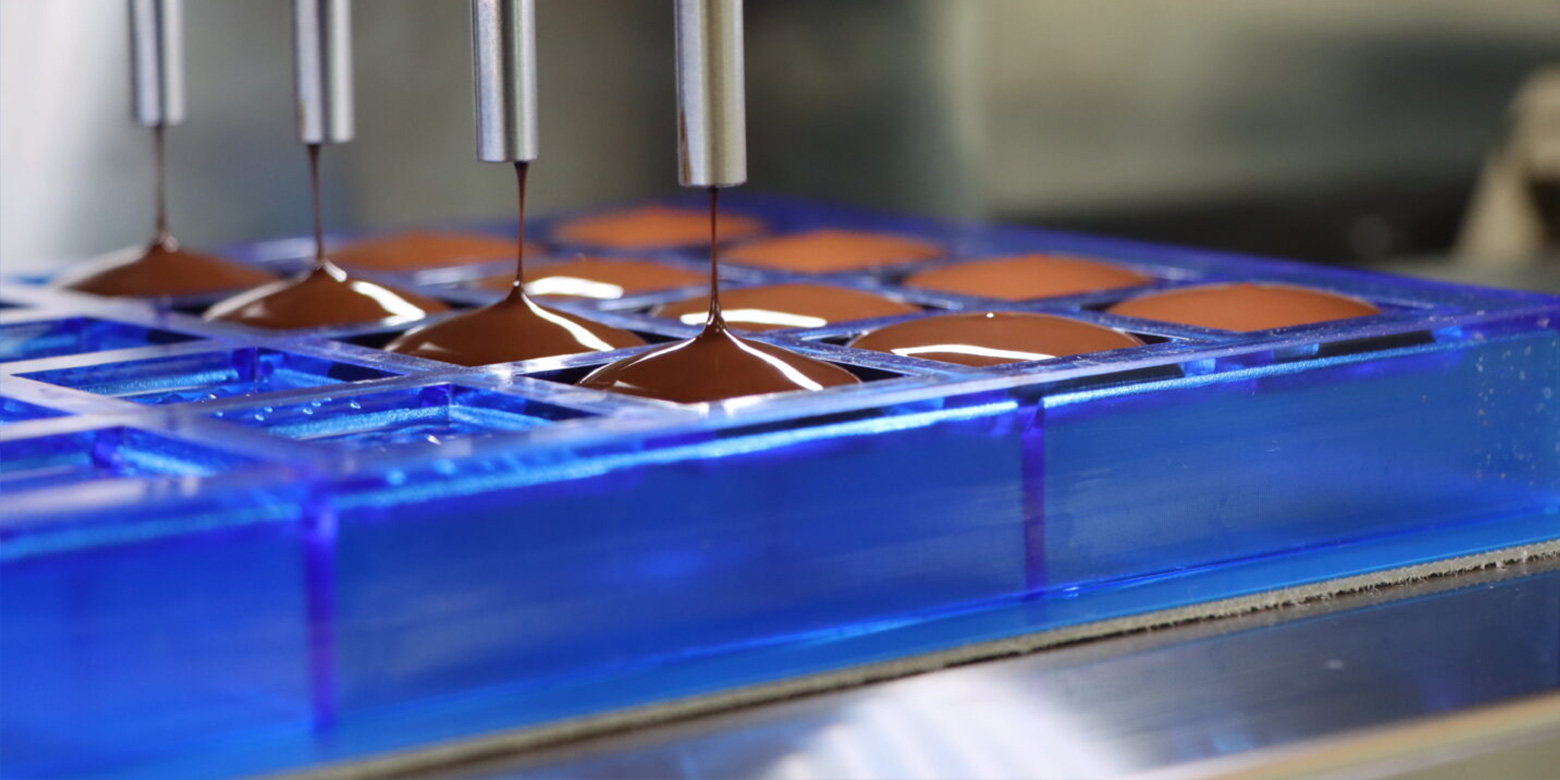

In the modern era of industrial manufacturing, 3D printing technology has revolutionized numerous industries. Among these, the food, cosmetics and pharmaceutical industries have taken advantage of the incredible possibilities offered for the production of special components with detectable plastics.

A composite material is a combination of two or more simple materials, in order to take advantage of the qualities of the constituents and to improve their mechanical characteristics.

Fibers and matrix are combined: the MATRIX acts as a binder and as a support (in compressive stress) and the FIBERS act as a reinforcement (in tensile stress).

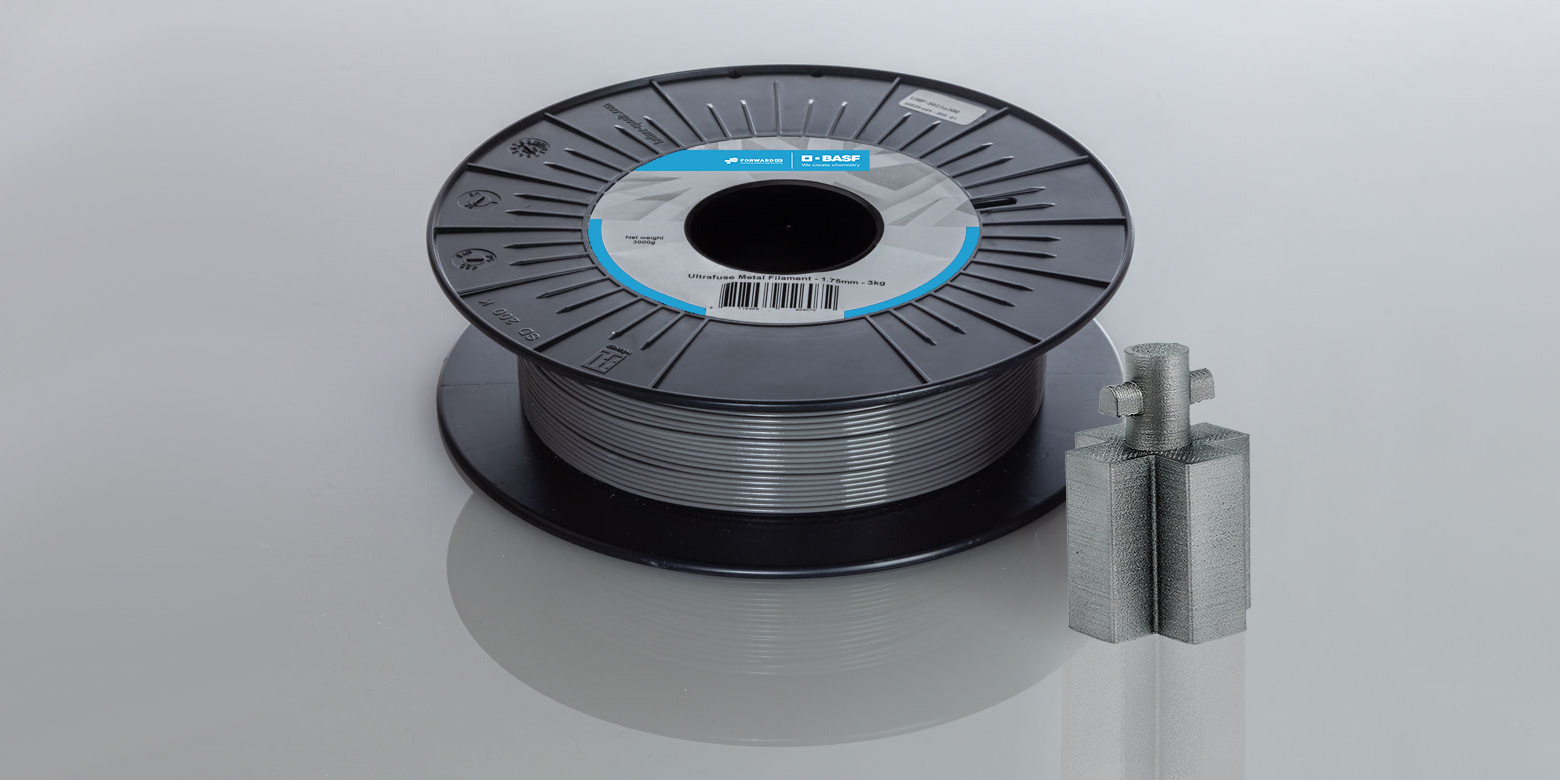

Ultrafuse® 17-4 PH is the BASF-branded metal filament that joins the Ultrafuse 316L filament, which already at the beginning of last year made metal 3D printing accessible to anyone.

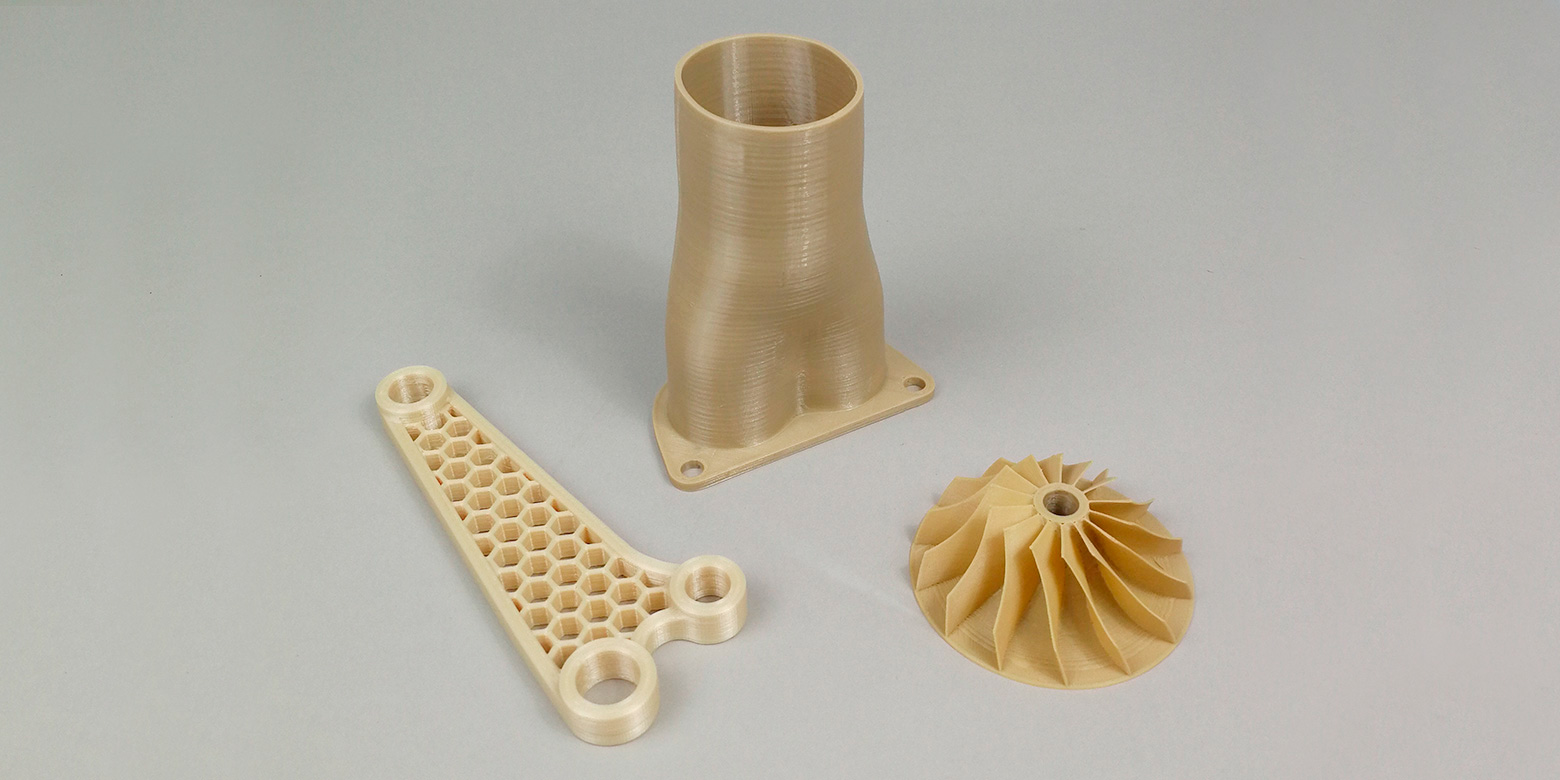

PPS stands for thermal stability, dimensional stability, chemical resistance and self-extinguishing in case of contact with flames.

"The best compromise between high performance, low cost and ease of printing."

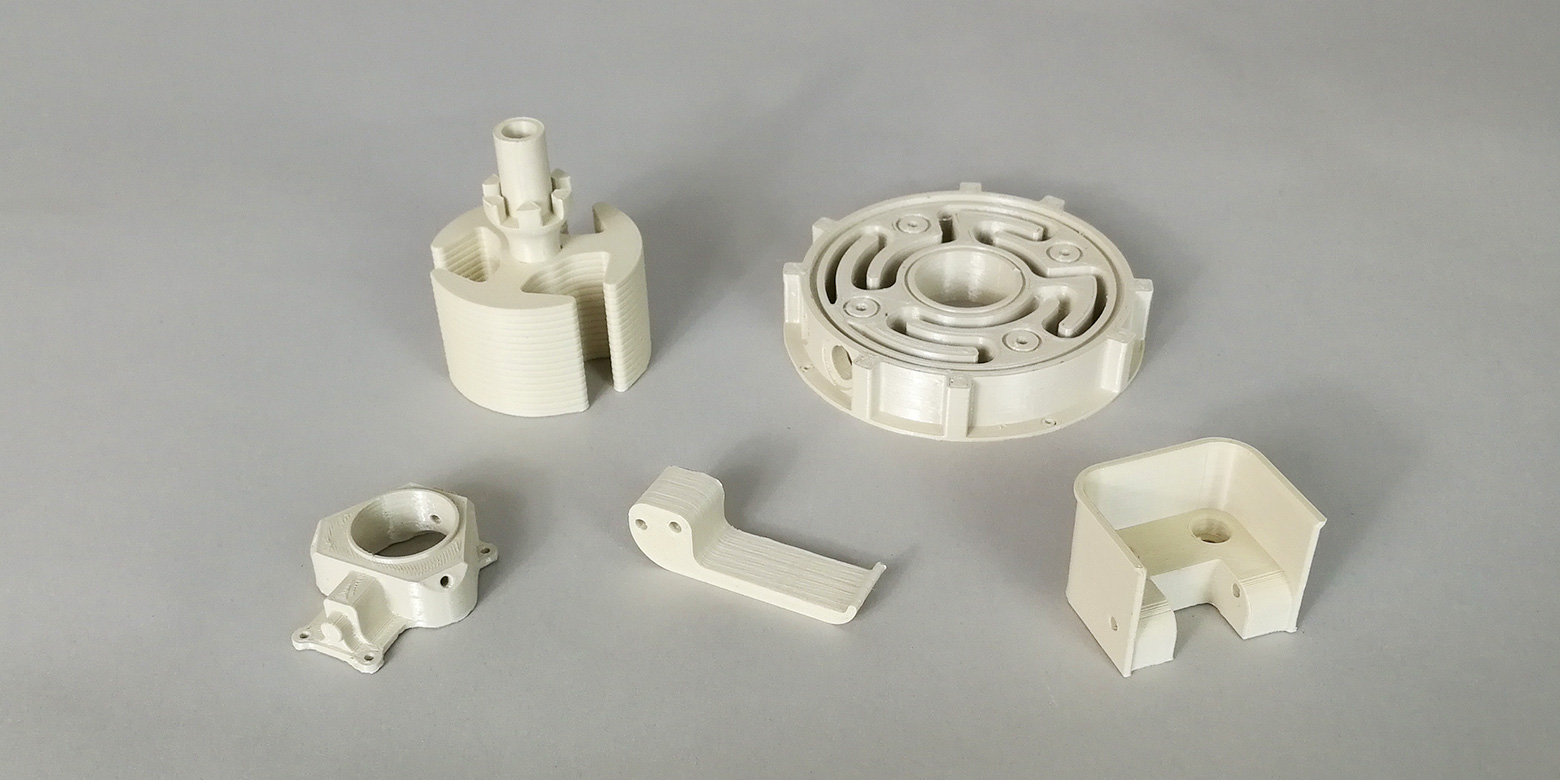

A recent survey by us has highlighted the growing demand for high-performance polymers, for ever more specific applications.

While almost all of the requests refer to standard or reinforced technopolymers, which can be processed by most of the professional desktop FDM printers on the market, there is also a growing interest in high-performance polymers that should operate in critical situations (high temperatures, radiation, high stresses).